Building a Rocker Bogie Rover

When I moved from northern Virginia to Palo Alto in 2010, I very quickly got sucked into the Maker movement. At that time, drones were just coming into hobbyist use, and I wanted my own version of the Army’s RQ-11 Raven that could be assembled from a backpack and launched by hand. I got to know Chris Anderson, former editor of Wired magazine, who had just founded a company called 3D Robotics (now 3DR) which sold open-source drones. I bought of one their hexacopters, which then led me down a rabbit hole from which I have not yet emerged. Once you learn how to use a microcontroller like an Arduino to take inputs from sensors and to control motors and servos, you can build lots of different things.

Among other things, meeting Chris made me a big fan of the open source community. When I couldn’t get my drone to work at first, I met him at the San Mateo Maker Faire—an annual event for tech hobbyists, now held all over the country. One of his engineers looked at my board, and showed me a mistake in the soldering. I built a number of drones after that, but finally decided to give it up when I realized that the stress of flying a drone was aggravating a heart condition. Drones can be very dangerous—my hexacopter was like a flying lawnmower, and I worried that if I hit someone with it I could do some serious damage.

___STEADY_PAYWALL___

At that point I decided to turn to building rovers that would stay on the ground. I built two. Rover 1 was based on an RC car chassis and was loaded with a video camera and a bunch of sensors. It could drive around the house completely autonomously; if it sensed it was nearing a wall, it would stop, back up, turn, and keep going.

Rover 2 was a larger one built on an aluminum and steel chassis that I constructed myself. This was the first time I had ever worked with metal, and found that I couldn’t really deal with metalworking tolerances. In particular, I couldn’t drill the hole patterns for the motor mounts by hand with sufficient accuracy to ensure that they would rotate properly without their shafts binding.

For that reason I bought my first CNC machine at another San Mateo Maker Faire around 8 years ago. My hope was that I could get it to drill the holes from a 3D computer model. At that point, CNC machines were themselves just becoming common for hobbyists, and were not that easy to use. Mine connected to the computer with an old-fashioned parallel port, which needless to say are not used on modern laptops. It didn’t work well.

At that point I got rid of all my drones and rovers and gave my collection of Arduinos and associated equipment to my sons David and John. (They actually made good use of this stuff and use microcontrollers in their professional activities these days.) I put the CNC machine away in the garage and didn’t touch it for many years.

However, the Covid lockdown sent me cycling through all of my previous tech hobbies, and last fall I decided to pull out my soldering iron and get back into robotics. The technology had moved on in great ways in the interim. Microcontrollers have proliferated like crazy, getting smaller, much more capable, and cheaper. The single board Raspberry Pi in its fourth version is actually a fully functional Linux computer; I use one now for newspaper reading every morning. I created a network of Raspberry Pis and Arduinos to create a home automation system that controls the lights in my house.

I pulled out the old CNC machine, junked the old control hardware, and hooked it up to an Arduino Uno with a Synthetos CNC shield running GRBL 1.1. The latter is open-source control software that is widely used on simple CNC machines. I also had to learn how to make the 3D models in AutoDesk’s Fusion 360, from which you can create the G-code to run the CNC machine. All of this took a couple of months to get working properly.

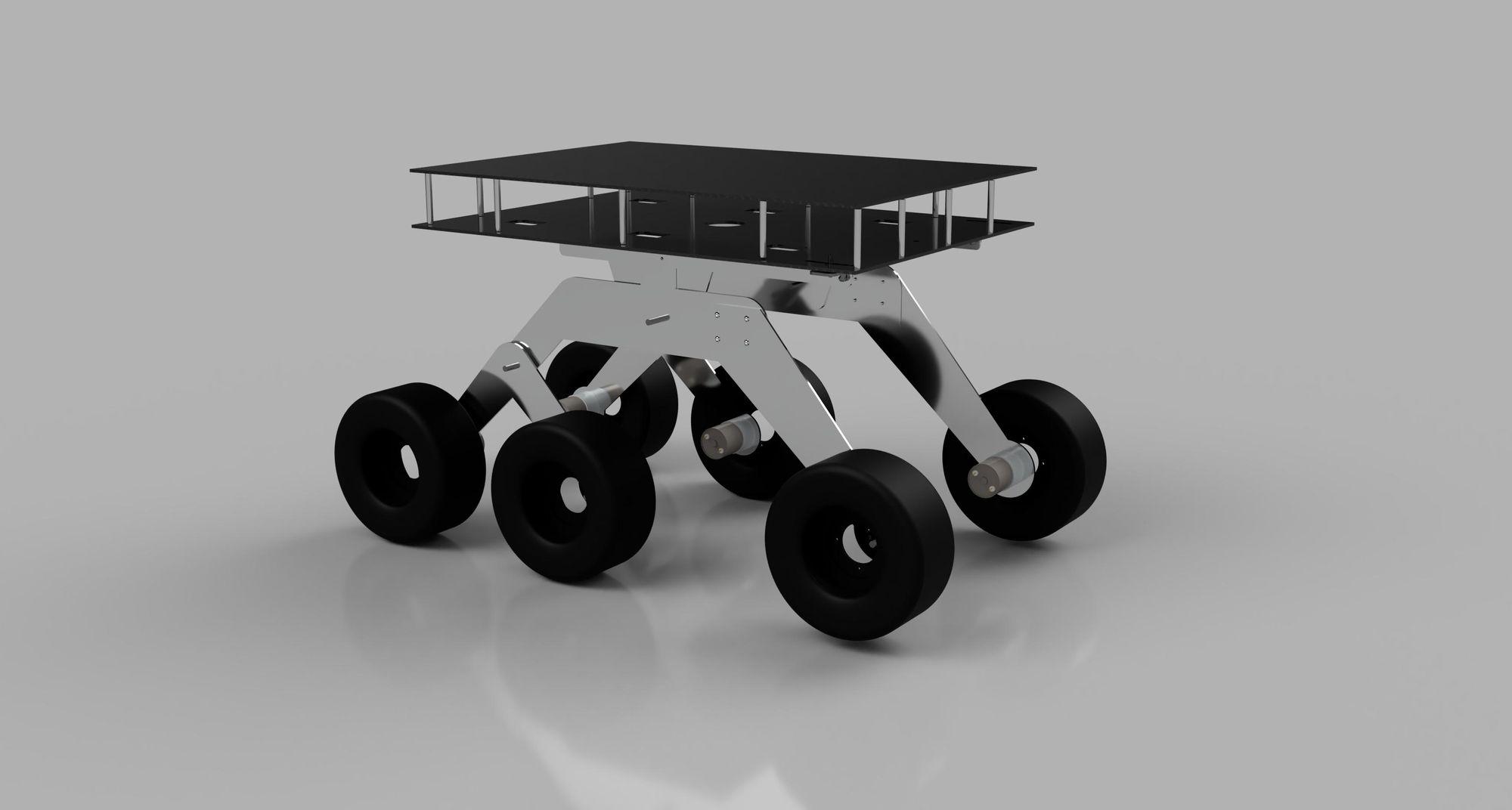

Which brings me to the current project, which is building a rocker bogie rover. The rocker bogie suspension was developed by NASA for its Mars rovers like Curiosity and the one that just landed on Feb. 17, Perseverance.

I built and programmed a small rover with this kind of suspension, roughly based on the code for my old Rover 1. My current goal is to build a significantly scaled-up version, but to make it out of metal rather than plastic as illustrated in this Fusion model.

After learning how to control a 3-axis machine, I bought a much larger Genmitsu CNC that was equipped with a powerful DeWalt router. I can now mill 1/8” aluminum sheets into rover parts. I saved the motors and tires from my old Rover 2, and am slowly collecting all the parts necessary for the new rocker bogie rover. I will continue to update on the progress of this project.

If you want to see pictures of this project on an ongoing basis, check out my Instagram feed at francis.fukuyama.

American Purpose newsletters

Sign up to get our essays and updates—you pick which ones—right in your inbox.

Subscribe